Arya Launch Vehicle

Arya-1: The Reusable Rocket

Arya-1 is a cutting-edge, two-stage reusable rocket developed by Orbit 2 Space, Designed with efficiency, durability, and simplicity in mind, Arya-1 represents a leap forward in reusable rocket technology.

Key Features:

Reusable First Stage:

The first stage is fully reusable and powered by seven rocket engines, each capable of producing 200 tons of thrust. This stage is designed for multiple reuses, leveraging patent-pending compartmentalized rocket propellant tank technology to maximize operational life and efficiency.Propellant Combination:

Arya-1 uses a highly efficient and environmentally friendly propellant mix of liquid propane and liquid oxygen (LOX), offering optimized performance during flight.Compact and Robust Design:

Built with practicality in mind, the rocket is constructed using stainless steel, a quick-and-dirty approach inspired by SpaceX’s Starship, offering durability and cost-effectiveness.- Height: Less than 40 meters, making it compact compared to most heavy-lift rockets.

- Diameter: 7 meters at the base, tapering to 5 meters at the top, ensuring stability and aerodynamics.

Innovative Design Philosophy:

Arya-1 is designed for ease of manufacturing and rapid deployment, ideal for commercial launches, satellite deployment, and space research missions. Its smaller size and advanced engineering make it a versatile choice for modern space applications.

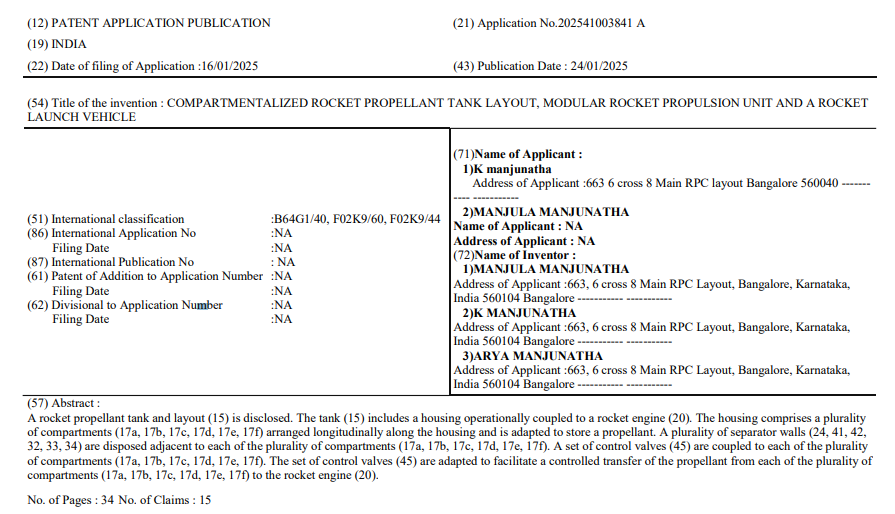

Patent Pending- Compartmentalized Rocket tank Layout technology.

The compartmentalized propellant tank layout offers several advantages that enhance the performance, safety, and reusability of rockets like Arya-1. Here are the key benefits:

1. Enhanced Structural Integrity

- Dividing the propellant tanks into compartments reduces internal stress caused by rapid propellant movement (sloshing) during flight.

- This design helps distribute loads more evenly across the rocket structure, increasing its durability and operational lifespan.

2. Improved Thermal Management

- By separating propellants into smaller, isolated compartments, the tank minimizes temperature gradients and heat transfer between different sections.

- This reduces the risk of overheating or cryogenic boil-off, maintaining propellant efficiency during prolonged missions.

3. Mitigation of Propellant Sloshing

- Compartmentalization reduces the free movement of liquid propellants inside the tank, preventing destabilizing slosh effects that can affect the rocket’s trajectory and stability during flight.

- This design simplifies guidance and control system requirements, improving reliability.

5. Optimized Propellant Usage

- Compartmentalization allows for better management of residual propellants, reducing waste and enabling more precise fuel usage for re-entry, landing, or extended missions.

6. Flexibility for Multimission Capability

- The modular nature of the design allows different compartments to be adapted for specific mission requirements, such as storing additional fuel for extended missions or accommodating specialized payloads.

7. Support for Reusability

- The compartmentalized layout improves the rocket’s robustness against the stresses of repeated launches and landings, enhancing the viability of reusing the rocket stages multiple times.

8. Lightweight Design with High Efficiency

- The design minimizes material wastage by using internal bulkheads and supports strategically, keeping the rocket lightweight while maintaining strength.